Electrical Theory & Applications for HVACR

Chapter 6: Troubleshooting

Page 115

but the boƩom switch is open. A voltmeter across terminals A and B of the top switch will read 0

volts because it is measuring a potenƟal difference between Line 1 and Line 1. Since the motor is

running, it is dropping 230 volts across the run winding (C and R terminals) of the PSC motor.

However, a voltmeter across terminals C and D of the boƩom switch will also read 0 volts. This

happens because Line 1 actually extends to the common terminal of the motor when it is running.

This would make terminals C and D of the boƩom switch both Line 1, and the voltage difference

between Line 1 and Line 1 is 0 volts. Actually, points A, B, C, and D are all Line 1.

Figure 6‐12 is a scenario where both an open switch and a closed switch read 0 volts. What

technicians must do when electrical troubleshooƟng is to ask themselves where Line 1 and Line 2 are,

not whether the switch is opened or closed. Measuring across the same line will always give 0 volts.

Measuring across Line 1 to Line 2 will always give the total circuit voltage, which in these examples

was 230 volts.

SYSTEMATIC TROUBLESHOOTING

Many service technicians are faced with troubleshooƟng refrigeraƟon and air condiƟoning systems on

a daily basis. Learning the most

efficient methods of troubleshooƟng

saves the service technician Ɵme as

well as the customer money. Good

systemaƟc troubleshooƟng techniques

are a win‐win situaƟon for both

customer and service technician.

Following is an example of a

systemaƟc troubleshooƟng method

incorporaƟng

a

symptoms/cause

method.

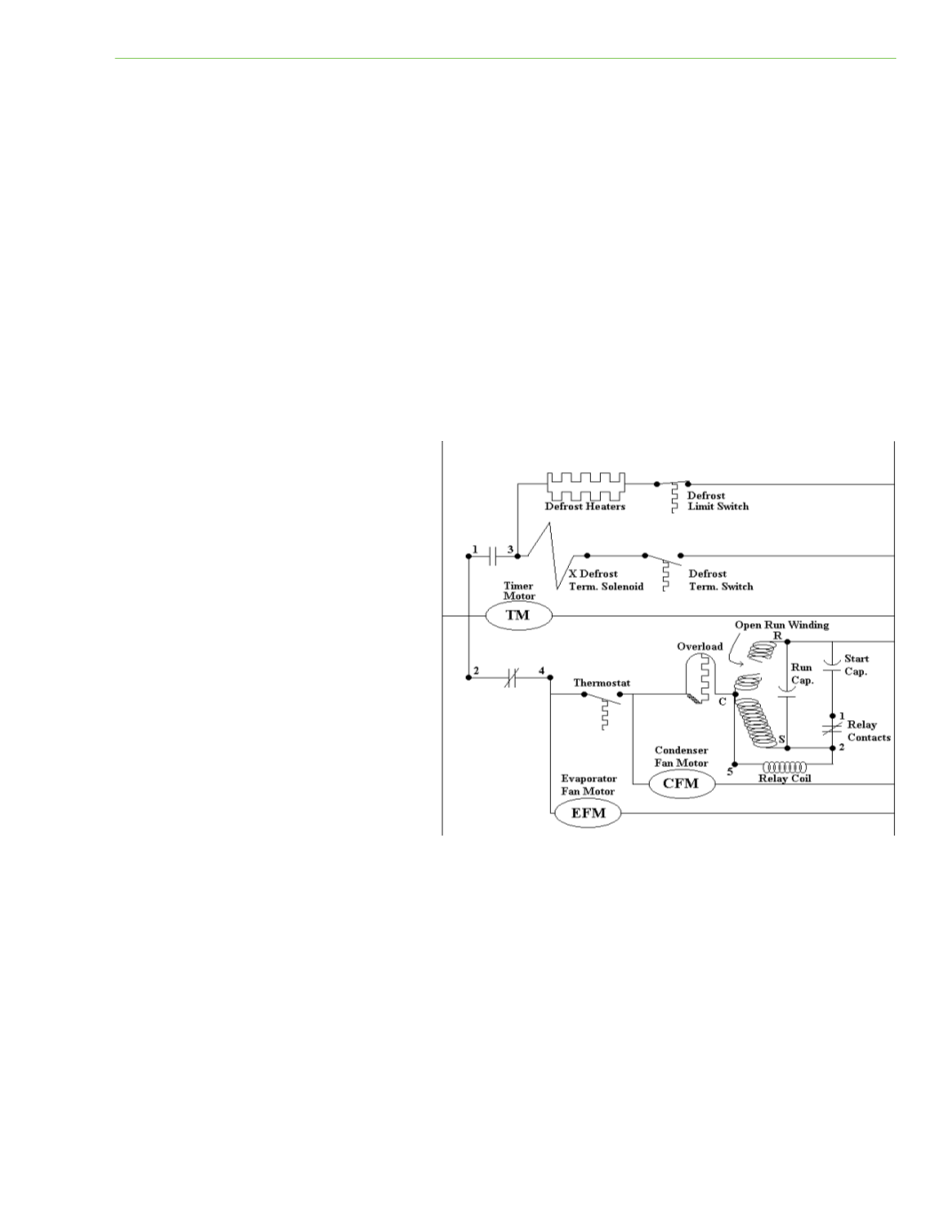

Figure 6‐13 illustrates an electrical

schemaƟc diagram showing a Ɵme

clock controlling a defrost circuit and a

refrigeraƟon circuit. NoƟce that in the

refrigeraƟon circuit, the compressor’s

run winding has been opened by a

motor overheaƟng problem. The

service call is a “no cooling” call for a

low‐temperature walk‐in cooler. Once the technician quickly looks the system over and listens for

any clues of what the problem may be, the electrical schemaƟc, if available, should be studied.

Understanding the logic or sequencing of the circuits before diving head‐over‐heals into the problem

is of utmost importance in systemaƟc troubleshooƟng.

In this scenario, an open run winding will cause certain symptoms not caused by other possible

system problems. For example, the technician listened to and examined the refrigeraƟon system and

then studied the electrical schemaƟc drawing. The service technician then lists the symptoms:

1.

Compressor motor hums and will not turn

2.

Compressor motor draws locked rotor amps (LRA)

Fig. 6‐13