Page 118

Chapter 6: Troubleshooting

Electrical Theory & Applications for HVACR

Locked Rotor Amps (LRA)? This is before the overload had opened. Figure 6‐15 illustrates this

scenario. NoƟce that a voltmeter placed across the R ‐and C terminals of the motor (the opened

winding) will again read 230 volts. In fact, all the voltages in Figure 6‐15 and Figure 6‐16 are the

same. Figure 6‐16 illustrates that whether the motor is running properly or if it has an open winding,

the voltage will sƟll read 230 volts across R and C. So how does the service technician determine if

the run winding is open or not? The answer is with an ohmmeter.

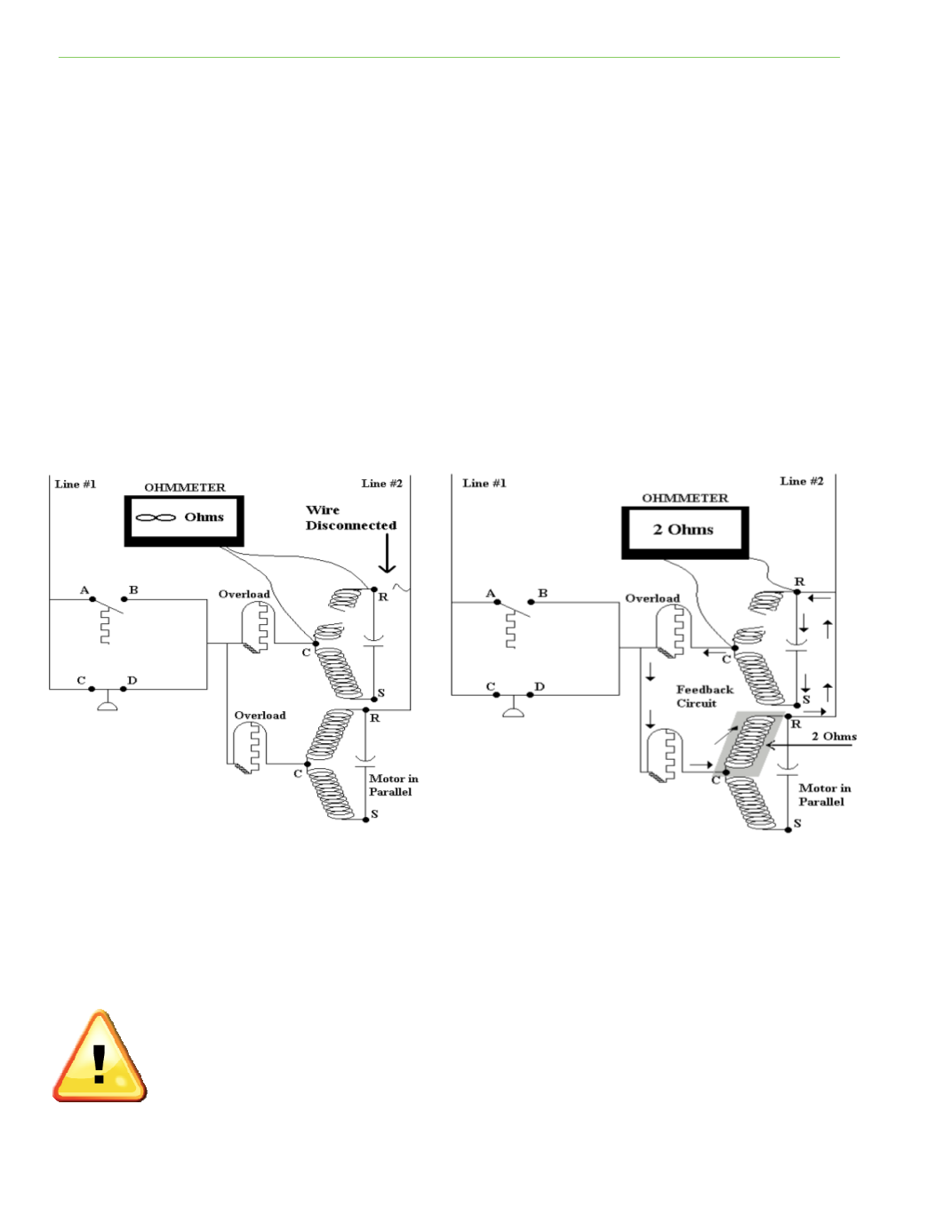

The service technician must shut down and disconnect one wire, either from the R or C terminal of

the motor (Figure 6‐17). DisconnecƟng the wire will prevent electrical parallel feedback from the

ohmmeter’s internal voltage source through another parallel electrical circuit. The technician must

then place an ohmmeter across the R and C terminals of the motor. The measurement will read

“infinite ohms” if the winding is open. This is the only way the service technician can tell if the

winding is open or not.

Figure 6‐18 shows a parallel feedback circuit from the ohmmeter’s internal voltage source if a wire

was not disconnected from the motor terminals. In this case, the ohmmeter reading would be 2

ohms. This could fool the technician into thinking the winding was sƟll good.

TESTING CAPACITORS

Capacitors (run or start) can be tested and the actual capacitance found using a capacitor tester found

on most digital meters. An ohmmeter can be used to check basic condiƟons of a capacitor, such as a

shorted or open circuit and whether or not the plates will take a charge.

When tesƟng a capacitor with an ohmmeter, the capacitor must first be discharged in

order to prevent damage to the capacitor or ohm meter. Do not short across the

terminals with a screwdriver; the proper method is to use a 15,000 ohm, two waƩ

resistor connected across the capacitor terminals. This will allow the current to dissipate

slowly and avoid damaging the capacitor.

Fig. 6‐18

Fig. 6‐17