Electrical Theory & Applications for HVACR

Chapter 6: Troubleshooting

Page 117

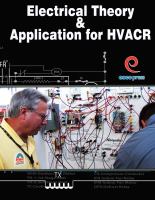

winding. Evaporator superheat, total superheat, and

condenser sub‐cooling, along with sucƟon pressure and

head pressure, must be taken for the system check. In

this case, the technician took a system check and found

the evaporator superheat to be very high at 40° and

the total superheat to be very high at 90°. Condenser

sub‐cooling was fine at 12°. Both sucƟon and head

pressure were low (see Figure 6‐14). The problem that

caused the overheaƟng was a faulty thermostaƟc

expansion valve. The valve would not open enough, and the enƟre low side of the system was being

starved. The compressor was a refrigerant‐cooled compressor. This caused the compressor to

overheat and cycle on its overload unƟl the run winding finally opened. Without this final system

check, the new compressor would surely fail in a short Ɵme.

VOLTMETER OR OHMMETER?

OŌen service technicians will encounter switches in series or parallel with electrical loads. Keeping

the electrical power on and using a voltmeter to voltage troubleshoot is the fastest and most reliable

method. However, there will be Ɵmes when a technician must switch to an ohmmeter and shut the

electrical power off in order to get to the root of the problem.

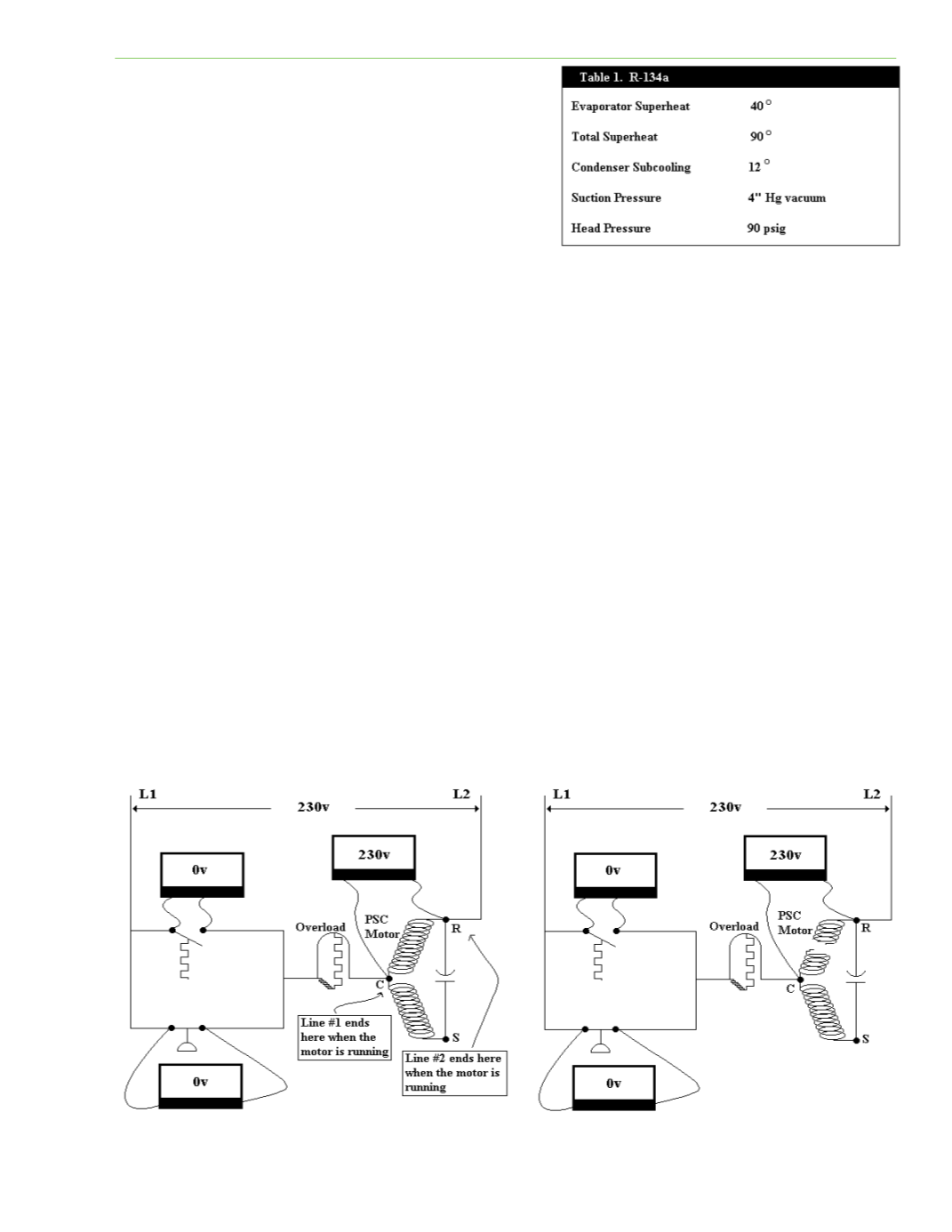

Figure 6‐15 shows an electric PSC motor in series with two switches that are in parallel with one

another. The voltage between points A and B (the open switch), in this case, would be zero volts

because the voltmeter would be measuring between Line 1 and Line 1. The voltage between points C

and D (the closed switch) would also be zero volts because of the voltmeter measuring between Line

1 and Line 1 again. Remember, the motor is running and dropping all of the 230 volts while it is

consuming power. A voltmeter across the R and S terminals of the PSC motor would read 230 volts

because the meter is measuring the voltage between Line 1 and Line 2, which is 230 volts.

Figure 6‐15 showed us that a voltmeter across the R and C terminals of the PSC motor would read 230

volts because it is measuring between Line 1 and Line 2. However, what would the voltage be

between R and C if the run winding between R and C opened, causing the motor to stall and draw

Fig. 6‐14

Fig. 6‐15

Fig. 6‐16