Electrical Theory & Applications for HVACR

Chapter 2: Circuits and Their Components

Page 31

condiƟoning). A three‐pole contactor has three sets of contacts and is used to control three‐phase

loads (for commercial and industrial).

It is normal for contacts to become piƩed and burned due to arcing when they open and close. Use

of a file or sandpaper to clean the contacts is not recommended; such

“cleaning” destroys contact surfaces and increases arcing. Large

amperage replacement contacts are usually available from local

suppliers.

The numbering system for contactors determines the direcƟon of

current flow through the contacts. It is standard policy for power

supply to enter at the top of the contacts and the load to be connected

to the boƩom. Line power (inlet) terminals are labeled L1, L2, and L3

and load (outlet) terminals are labeled T1, T2, and T3, according to the

number of poles.

CONTACTOR COIL BURN-OUT

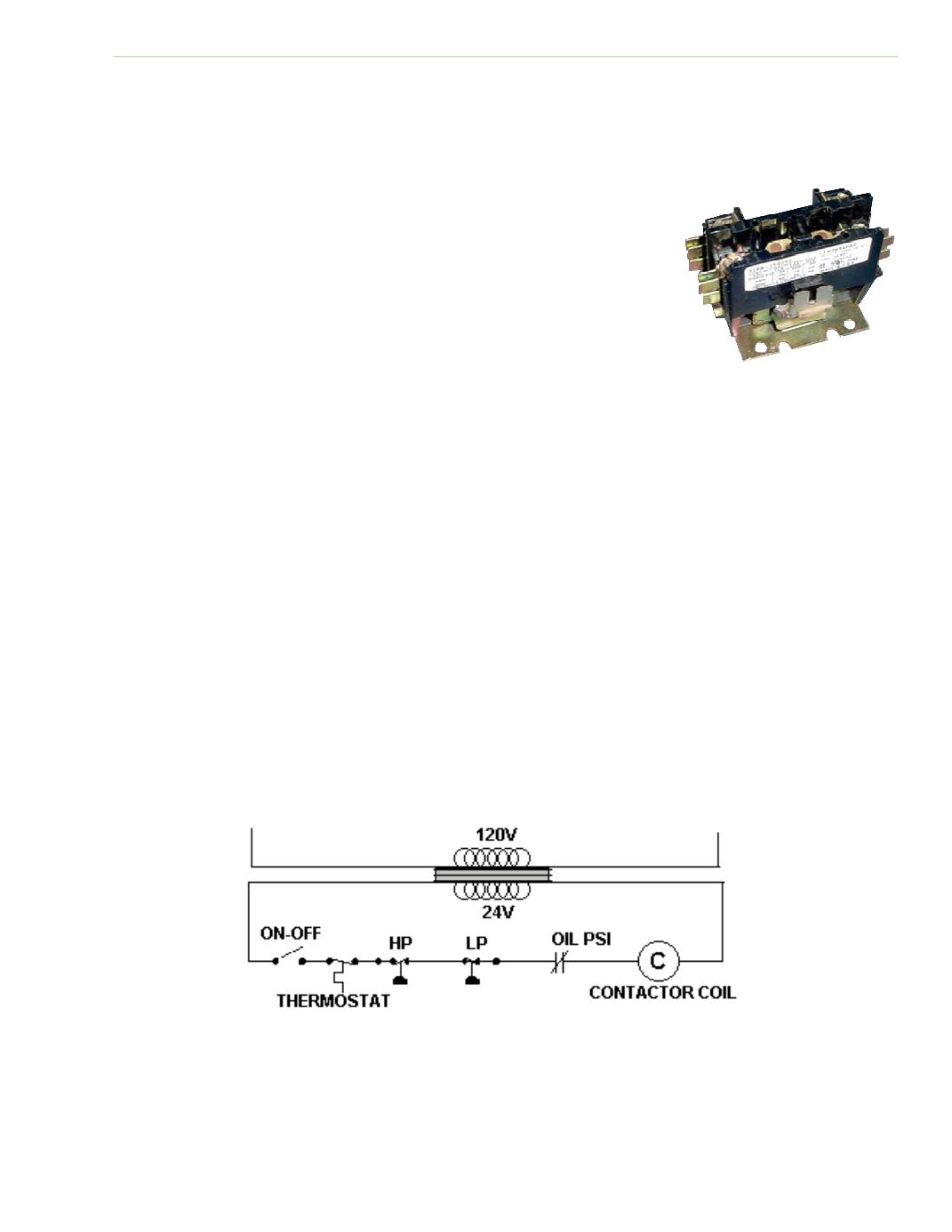

The magneƟc coil is located inside the contactor but is not electrically connected to the main

contacts. Because the coil is a separate device, coil voltage can be different than voltage at the main

contacts. The coil has its own terminals for making electrical connecƟons, and replacement of the coil

is easy. Coils may be 24, 120, or 230 vac. And contacts may be rated 15 to 60 amperes. Because the

coil is electrically separate from the main contacts, it is common pracƟce to use lower voltage to

operate the coil. ResidenƟal systems generally use 24 vac. control system. Current in the control

circuit is safer and permits the use of standard switching devices and class‐two thermostat wire. A

step‐down transformer is used to obtain lower control circuit voltage.

Any number of contacts and safety control switches can be located in the control circuit. Contacts for

these controls are connected in series with the coil and can include overloads, thermostats, pressure

controls, fuses, limit switches, flow controls, or oil pressure controls. All switches in the control circuit

in Figure 2‐26 must be closed before the coil can be energized. However, any switch can disconnect

power to the coil and stop the motor. Some safety controls have a manual reset, while others have

an automaƟc reset.

Fig. 2‐25: Single‐pole contactor

Fig. 2‐26: All control switches must be closed to energize the coil; any switch can open and

stop the motor