Electrical Theory & Applications for HVACR

Chapter 3: Motors

Page 59

When recording rotaƟon direcƟon, always indicate which end of the motor is being viewed. If the

shaŌ is turning to the right, rotaƟon is clockwise (CW). If the shaŌ is turning to the leŌ, rotaƟon is

counter clockwise (CCW). Not all motors have wiring connecƟons that allow the motor to be reversed

in the field.

DISCONNECTING THE START WINDING

The only purpose of the start winding in a split‐phase motor is to start the motor. Once the motor

has started, the start winding must be removed from the circuit or it will burn out. FracƟonal

horsepower (Hp) motors use a centrifugal switch or relay for disconnecƟng the start winding aŌer

start‐up. Open motors have a centrifugal switch inside the motor that is connected in series with the

start winding.

Motors of less than one horsepower are called

fracƟonal horsepower motors. For example, 1/2 hp

and 1/4 hp are fracƟonal horsepower motors.

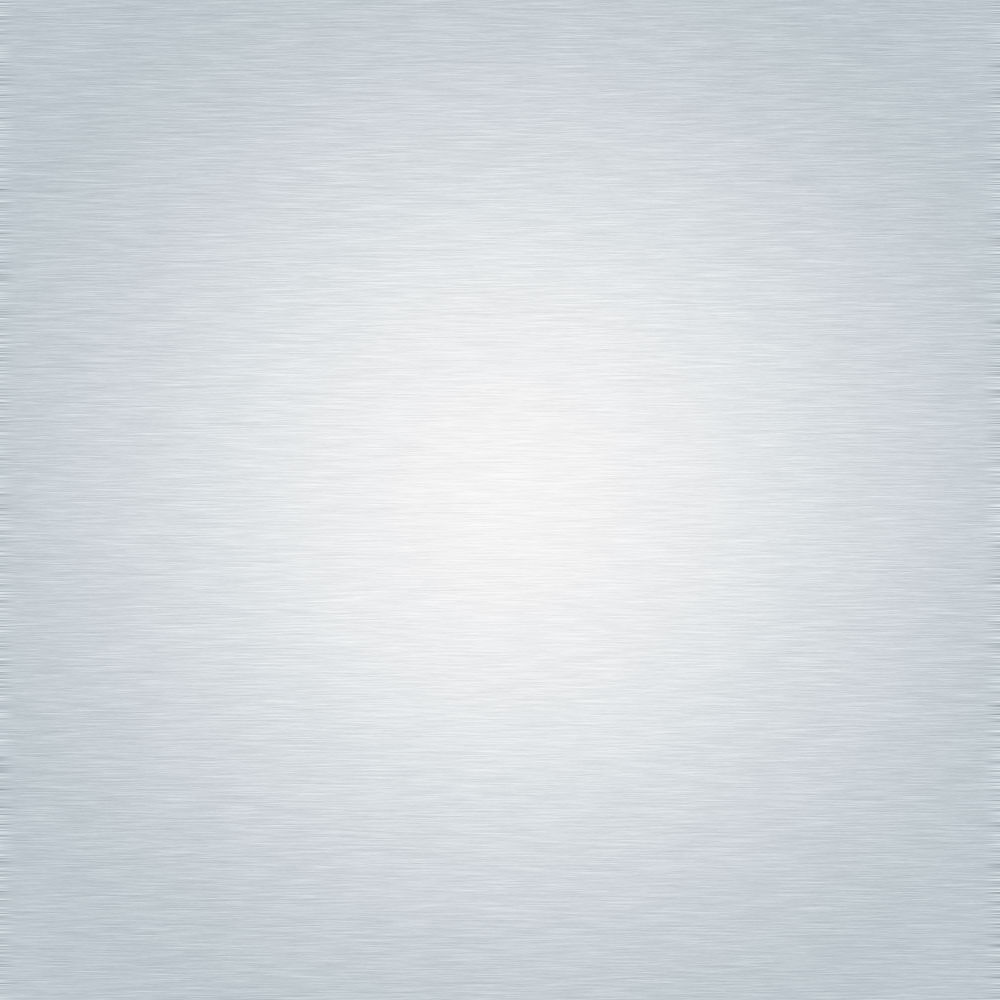

The contacts on the centrifugal switch in Figure 3‐10

are closed when the motor is not running. When the

motor achieves 75 percent speed, enough centrifugal

force is produced to make a pair of weights swing

outward and open the switch. When the motor stops,

springs pull the weights back and the switch is closed

for the next start‐up. Failure of the centrifugal switch

to open permits the start winding to remain in the

circuit, resulƟng in high amperage. In this case, the

motor overload should stop the motor.

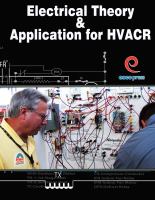

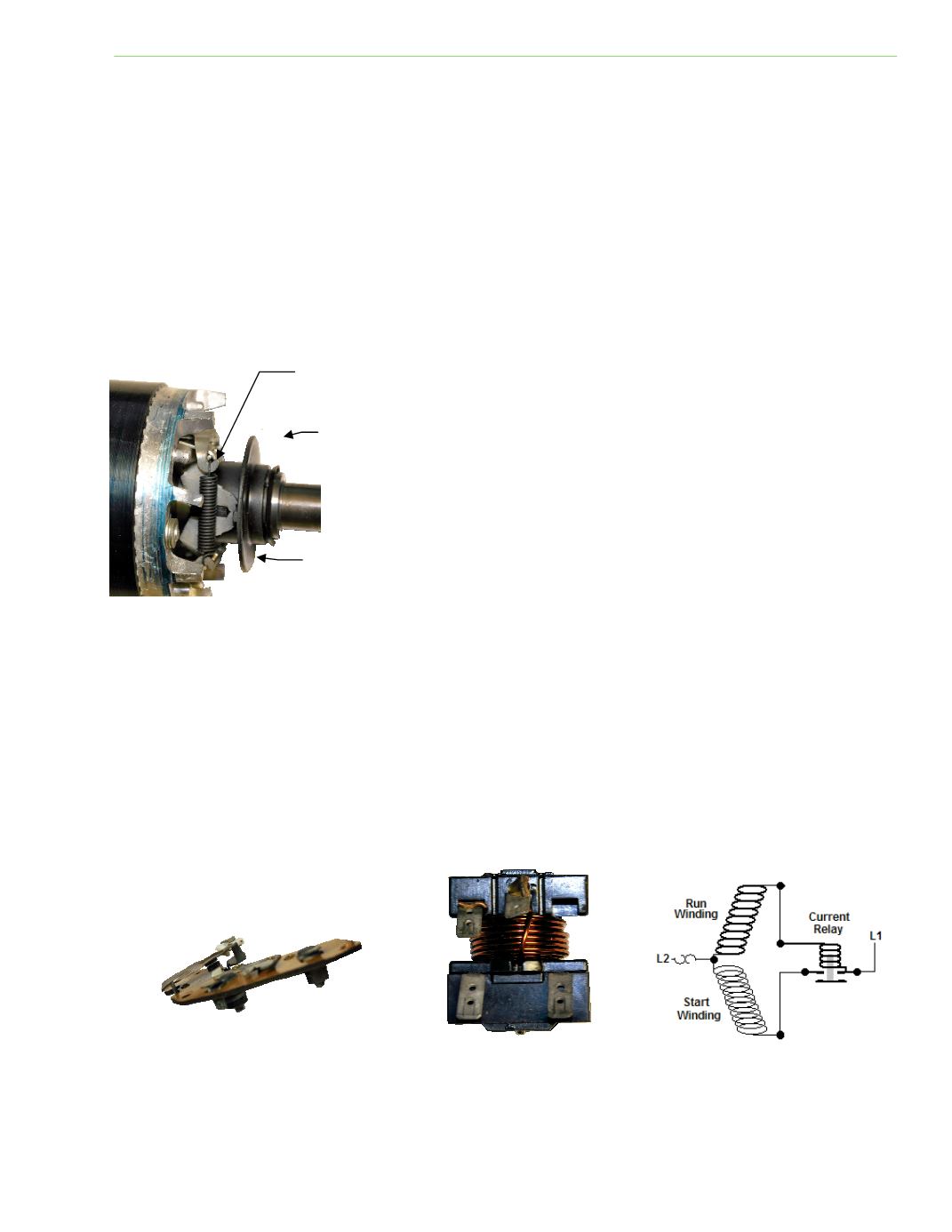

A current relay or posiƟve temperature thermistor (PTC) can be used on fracƟonal horsepower, open

motors, or sealed refrigerant compressors to disconnect the start winding. The current relay coil

produces a magneƟc field from the high starƟng current, liŌing the contacts closed and energizing the

start winding. AŌer the rotor starts turning, current decreases and the contacts open.

Fig. 3‐11: Centrifugal switch contacts

Fig. 3‐12: Current relay

Fig. 3‐10: Centrifugal switch

MOVABLE COLLAR

CONTACT POINTS

CENTRIFUGAL WEIGHTS

Fig. 3‐13: Current relay wiring