Page 62

Chapter 3: Motors

Electrical Theory & Applications for HVACR

ELECTRONICALLY COMMUTATED MOTORS (ECMs)

ECMs run at very high efficiencies for single‐phase motors. An

ECM is a brushless DC motor operated by an aƩached variable

frequency drive. The rotor has three permanent magnets

mounted on the outside to create three poles. The stator has

three windings, just as a three‐phase motor does. An

electronic inverter control mounted to the back of the motor

pulses a DC voltage, to energize one winding at a Ɵme. The

frequency drive can be set for the proper speed for heaƟng

and cooling or variable speed operaƟon, depending on the manufacturer’s controller.

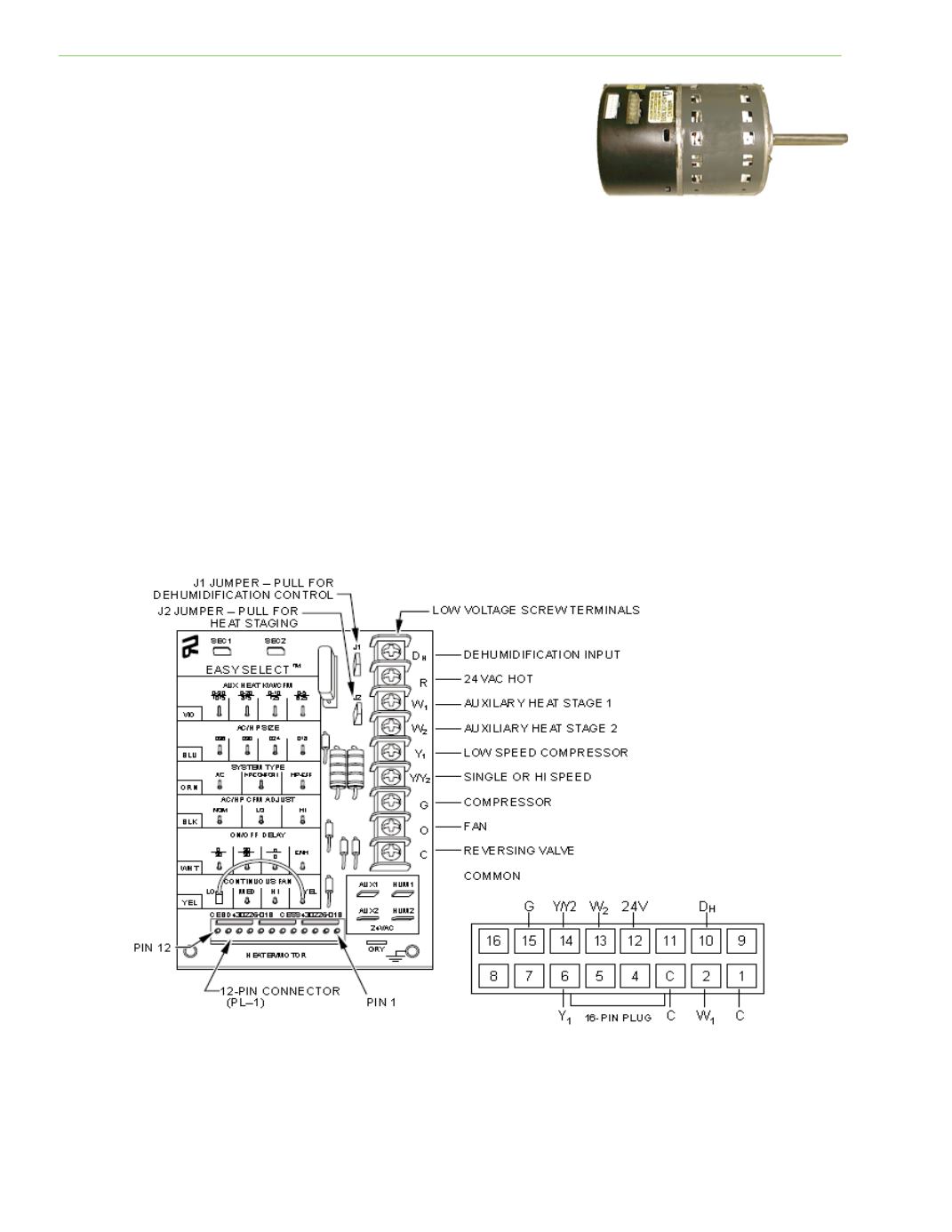

When used as a mulƟ‐speed motor, the air handler has a circuit board with dipswitches or wire

jumpers that must be selected for proper cooling or heaƟng CFM. Electronic thermostats monitor the

indoor relaƟve humidity as well as temperature, and vary blower speed to control humidity and CFM

for stages of heaƟng and cooling. OperaƟon of the ECM on a blower is quite different than on a

regular motor. When blower air flow is blocked, the motor current increases to maintain the correct

RPM for the air flow seƫng, whereas in a PSC or other motor, current decreases with air flow. This

inherent property of ECM blowers allows for operaƟon at a higher duct staƟc pressure. The motor

saves energy by running at approximately 50 percent cooling speed when the thermostat fan switch is

set to the “conƟnuous” posiƟon.

Fig. 3‐19: Electronically commutated motor

Fig. 3‐20: ECM control board