Electrical Theory & Applications for HVACR

Chapter 3: Motors

Page 67

FULL LOAD AMPS (FLA)

Full load amps (FLA) or rated run load amps (RLA) refers to the amperage a motor draws when at

normal speed and fully loaded. Most inducƟon motors operate at less than FLA because the motor is

rarely working at fully loaded condiƟons. Overload occurs when amperage exceeds a percentage of

the FLA raƟng or motor heat gets to high.

OVERLOAD PROTECTORS

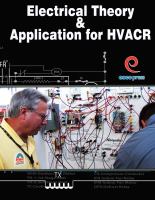

An overload protector is a device that protects a motor

against overload condiƟons. There are a variety of

overload protector types, and the type commonly used

depends on the type of motor and its applicaƟon. It is

common for a fracƟonal horsepower, single‐phase AC

motor to have an overload with a snap‐acƟng bimetal disc

that makes and breaks a set of contacts. Excessive

current causes the bimetal disk to deflect and open the

circuit. When cooled, the disc returns to the closed

posiƟon.

Repeated opening and closing of the overload is called cycling. ConƟnuous overload cycling is a

warning that the motor is in danger of a burnout. It is important to isolate and repair the cause of

the overload to prevent damage to the motor.

Another type of overload protector is an internal overload protector located inside the motor

windings. When checking motor windings, do not condemn the motor unƟl allowing sufficient Ɵme

for the internal overload to reset. The overload is acƟvated by temperature and current and may

take four to eight hours to reset.

When servicing a motor that has tripped on overload, be sure to disconnect it from the

power source. The motor could suddenly restart when the overload resets.

THREE-PHASE MOTORS

Three‐phase motors are very common in commercial and industrial applicaƟons. They are smaller

and more efficient than single‐phase motors of equal horsepower. Three‐phase motors have high

starƟng torque and high running torque, without the use of start windings or capacitors.

For proper operaƟon, all three supply wires (L1, L2, and L3) must be

connected to the motor terminals. The safety ground (green) wire is

included for equipment ground. This grounding wire is connected to the

motor frame to provide an escape for electrons in case the motor

windings become shorted to the metal frame.

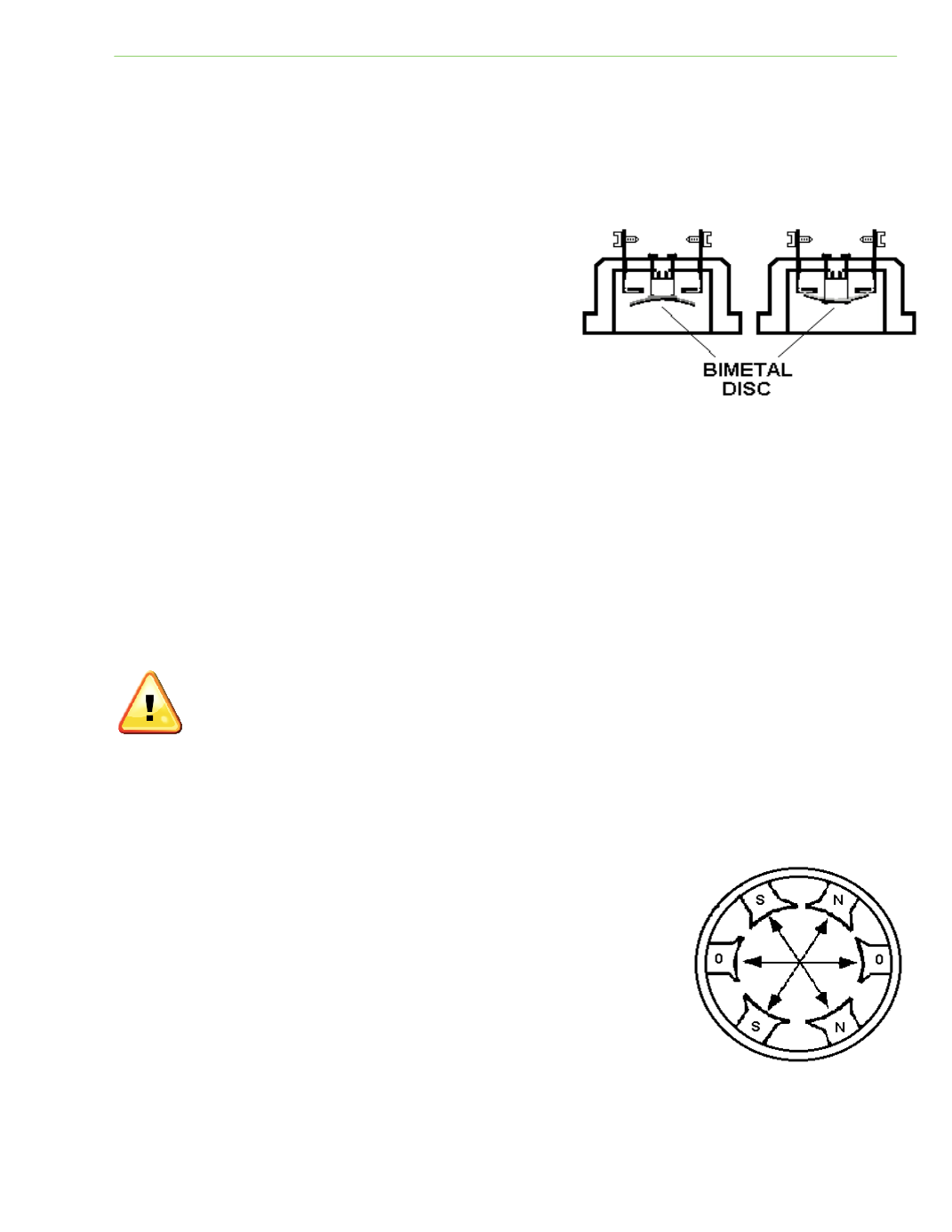

Three‐phase motors have three pairs of stator poles; one pair for each

supply wire. Each winding produces a north and south pole; this is called

one pole per phase. A typical three‐phase motor has three pairs of

stator poles, meaning three north and three south poles. Each north and

south combinaƟon is located directly opposite another. These poles are

equally spaced in a circle, exactly 60 degrees apart.

Fig. 3‐28: Overload protectors use a snap‐

acƟng bimetal disc to break a set of contacts

Fig. 3‐29