Electrical Theory & Applications for HVACR

Chapter 2: Circuits and Their Components

Page 23

require all electrical wires to be installed inside metal conduit pipes (not plasƟc). This metal‐to‐metal

pathway should be grounded by connecƟon to a grounding electrode or to the steel framework of the

building (which is grounded).

CONDUCTORS

Electrical wires are used as conductors to provide the necessary free electrons and serve as a pathway

for electron flow. These wires are used to connect devices and switches to complete an electrical

circuit. Silver, copper and aluminum are good conductors because they have high conducƟvity and

low resistance to current flow. In general, any

material that has three or less electrons in its outer

orbit, called the valance ring, is considered a good

conductor. Copper is the most commonly used

conductor. Copper has a single electron in its valance

ring.

The material’s ability to conduct electricity is referred

to as its K Factor. (ConducƟvity.)

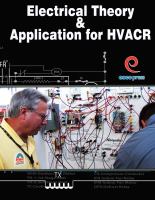

The amount of current a conductor can safely carry

without becoming overheated is limited. This current‐

carrying ability is called ampacity. The ampacity of a

conductor depends upon the wire’s diameter, length,

locaƟon, type and quality of insulaƟon. The chart

shown in Figure 2‐8 is a parƟal list of wire sizes,

resistance, and ampacity for standard sizes of copper

and aluminum wires based on American Wire Gage

(AWG).

Consult the NaƟonal Electrical Code (NEC) book for a

complete list of up‐to‐date informaƟon. No. 12 copper

wire is probably the most commonly used wire size. It

is oŌen used when a smaller wire would be approved.

Other than cost, there is no problem with over‐sizing

a wire. Under‐sizing causes severe problems due to

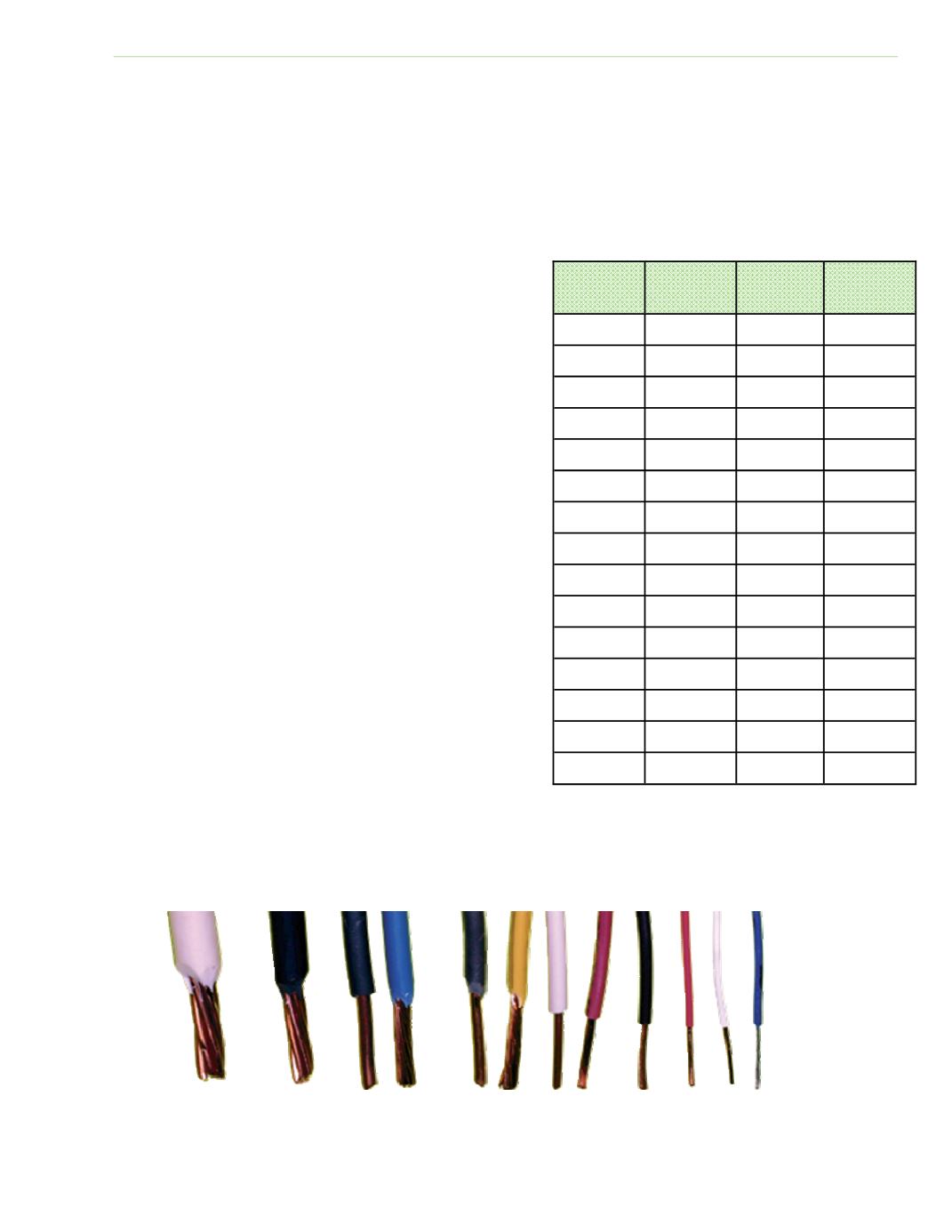

overheaƟng. Figure 2‐9 illustrates a sample of various

wire sizes for both solid and stranded wires.

Fig. 2‐8: Ampacity of commercial wire

Gauge No.

(AWG)

OHMS per

1000 FEET

Ampacity

Copper

Ampacity

Aluminum

0000

0.050

230

180

000

0.062

200

155

00

0.080

175

135

0

0.100

150

120

1

0.127

130

100

2

0.159

115

90

3

0.202

100

75

4

0.254

85

65

6

0.40

65

50

8

0.645

50

40

10

1.02

30*

25

12

1.62

20*

18

14

2.57

15*

16

4.10

10*

18

6.51

5*

*Load current raƟng and over‐current protecƟon shall

NOT exceed these figures.

Fig. 2‐9: Wire size and type determines current carrying ability (ampacity)