Electrical Theory & Applications for HVACR

Chapter 2: Circuits and Their Components

Page 25

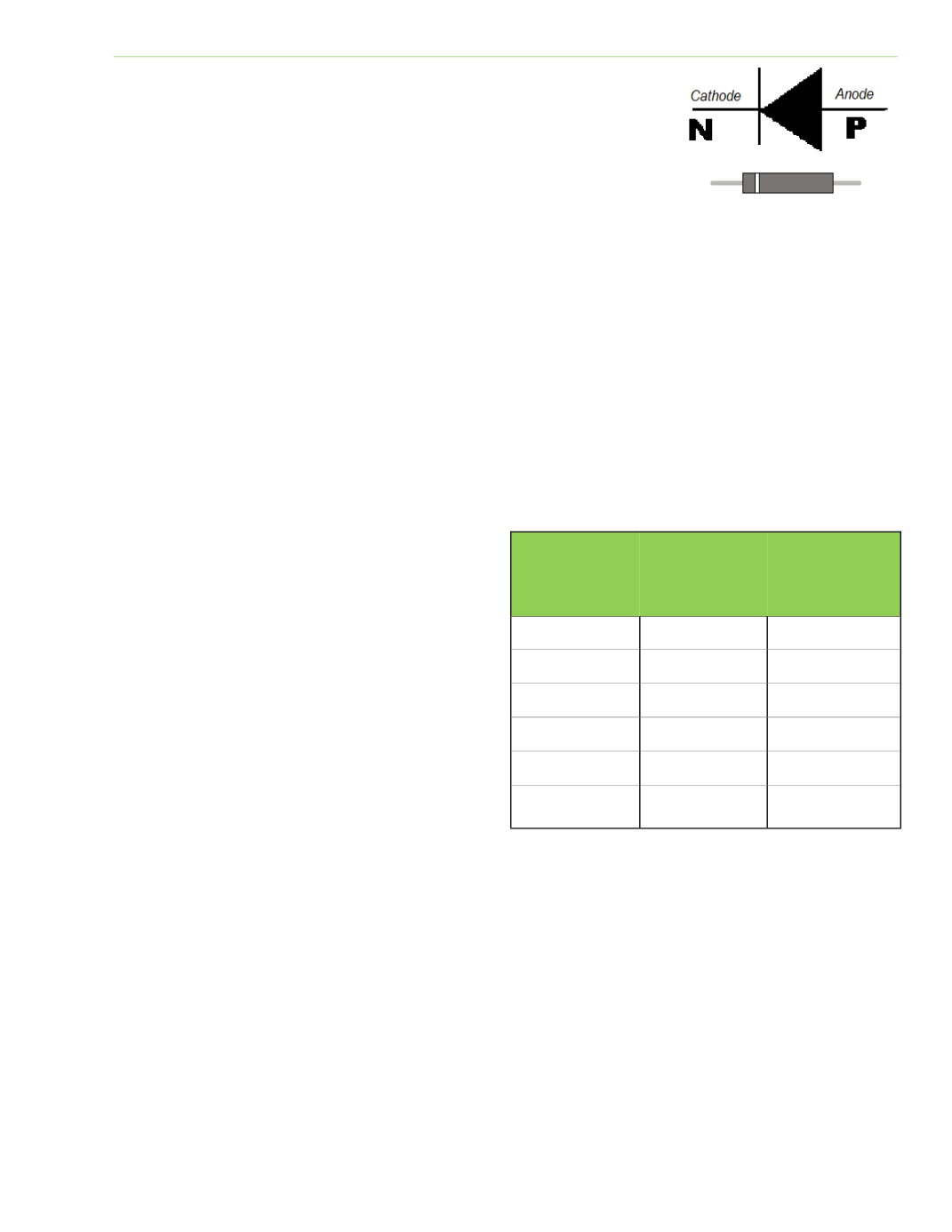

An electrical check valve can be created by sandwiching pieces of N‐

Type and P‐Type material together. Electrons can flow into the N‐type

material and out of the P‐Type material, but electrons aƩempƟng to

enter the P‐Type material are blocked and no current flows. This

simple solid state device is called a diode. A diode is represented in

electrical schemaƟcs by the symbol in Figure 2‐13.

CIRCUIT PROTECTION

Overcurrent occurs when excess current is flowing through a wire.

This causes the wire to become hot and presents a serious hazard. Overcurrent can be caused by a

variety of electrical problems such as loose connecƟons, ground fault, short circuit, defecƟve

resistance, or too many loads. An overload describes an overcurrent (between two and ten Ɵmes

the rated current.) A ground fault describes an overcurrent which runs to ground and may be

hundreds of Ɵmes the rated current. A ground fault is VERY dangerous.

Fuses and circuit breakers protect a circuit against overcurrent. The amperage raƟng of a fuse must

not be greater than the ampacity of the wires being protected. Fuses and circuit breakers are used

to detect excessive load current and open the circuit before danger arises. Examine the fuse clamp

holder for discoloraƟon or loose connecƟons; this indicates an overheated connecƟon. It is standard

pracƟce to locate fuses in the main power supply

and in each branch circuit. A blown fuse in a

branch circuit helps confine the problem to a

specific area. Fuses, overloads, and circuit

breakers protect wires and equipment, not

people.

The amperage and voltage raƟng of a cartridge

fuse determines the physical size of the fuse.

Fuse holding devices are sized according to the

same procedure. This helps prevent oversizing

fuses on circuits designed for a certain maximum

amperage. Figure 2‐14 illustrates fuse

dimensions in inches according to voltage, and

amperage raƟngs of the fuses.

Cartridge fuses are available as ordinary fuses (one‐Ɵme blow) or dual‐element. Dual‐element, or Ɵme‐

delay, fuses permit an overload of short duraƟon, but blow instantly if a short circuit occurs. Time‐delay

fuses are necessary when fusing circuits for electric motors. Screw‐in or Ɵme‐delay fuses are sized up to 30

amperes. If the view port on a screw‐in fuse is blackened or the skinny part of the element is burned, the

fuse has experienced extreme overload. If a port reveals a collapsed spring inside, the fuse has experienced

a slight overload. Round cartridge fuses are used up to 60 amperes and knife‐blade contacts are used for

fuses over 60 amperes. It is important that fuse ends make Ɵght contact in the fuse holder. Loose

connecƟons or high air temperatures around a fuse reduce the amperage raƟng and cause needless

shutdowns. Remember never to pull a fuse under a load, and always use a fuse puller to remove cartridge

fuses.

Fig. 2‐13: SchemaƟc symbol for

diode

AMPERAGE

RANGE

250 V

FUSE LENGTH

(INCHES)

600 V

FUSE LENGTH

(INCHES)

1/10 to 30

2

5

35 to 60

3

5 1/2

70 to 100

5 7/8

7 7/8

110 to 200

7 1/8

9 5/8

225 to 400

8 5/8

11 5/8

450 to 600

10 3/8

13 3/8

Fig. 2‐14: Amperage and voltage determine fuse size